INOX-TOTAL

Particularly suitable for work on stainless steel.

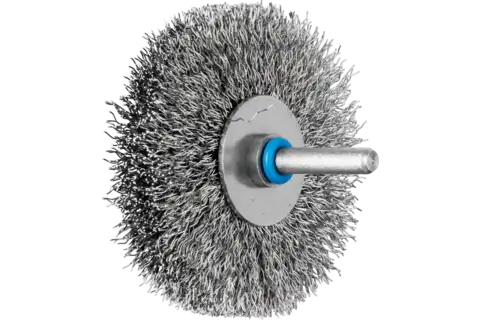

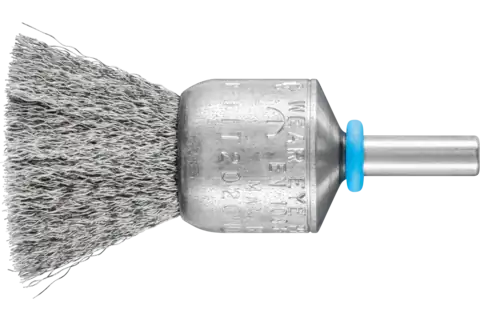

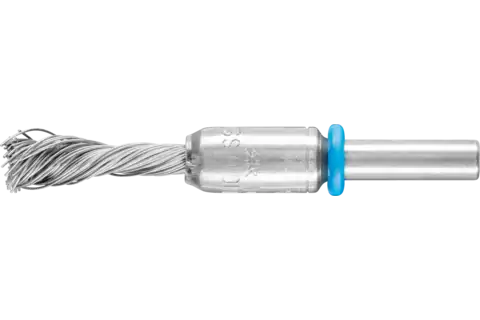

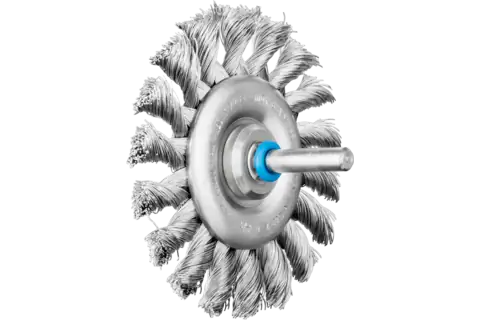

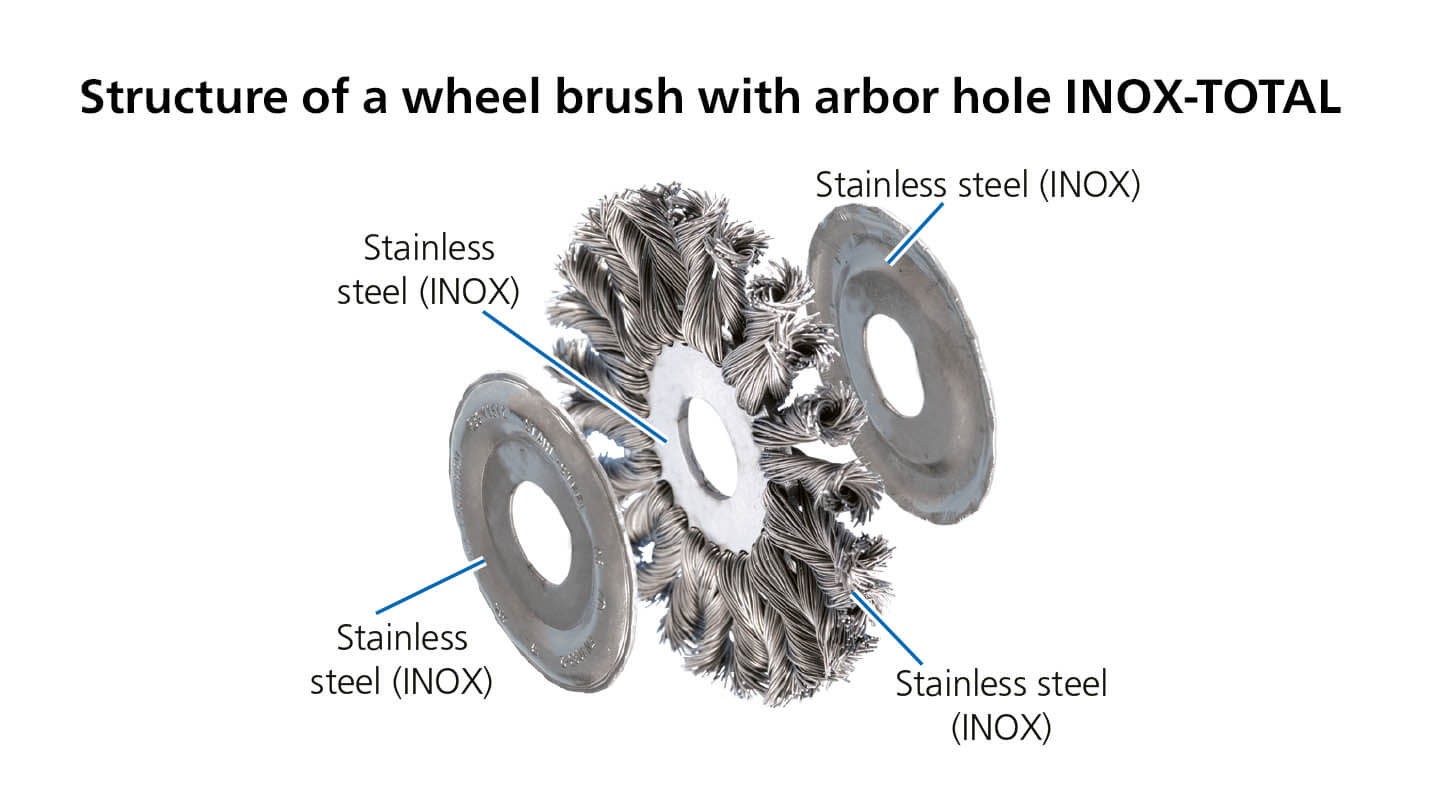

In addition to brushes with a stainless steel filament, PFERD TOOLS also offers brushes for work on stainless steel (INOX) with the INOX-TOTAL type.

These are characterized by the fact that all parts of the brush are made of stainless steel in quality 1.4310 (V2A), which ensures optimum corrosion protection. They are particularly well-suited to use in extremely critical environments. The stainless steel wire (INOX) used withstands temperatures up to 450°C.

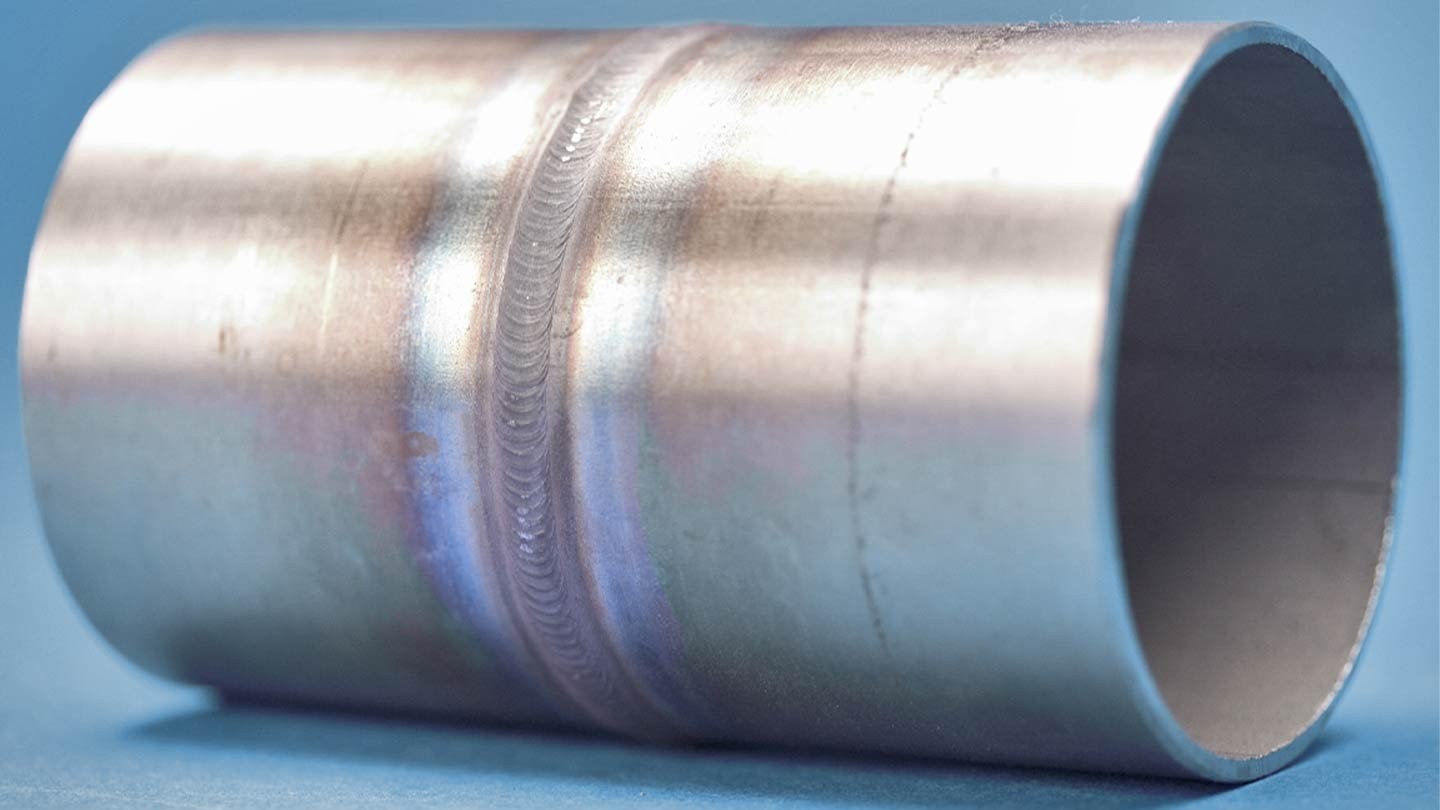

The INOX-TOTAL brushes are ideal for brushing work such as deburring, cleaning, and removing heat discolouration and oxide layers.

How to avoid common mistakes

| Causes of corrosion | Solution |

|---|---|

| Structure has changed because too much heat has built up. | Avoid heat using the following methods:

|

| Contact between the workpiece and the parts of the brush that are made of steel. |

|

| Mixture of work on steel and stainless steel (INOX). |

|

| Wire particles introduced into the surface. |

|

| Stock removal rate is too low | Removal of deep structural changes

|

Stainless steel (INOX) – a material with a successful future ahead of it

The patenting of the first rust-resistant steel at the beginning of the previous century marked the dawn of the enduring success of this new material. After all, rust gradually destroys iron and steel…

Stainless steel (INOX) – recommendations for use

- What is the most cost-efficient way of working on stainless steel (INOX)?

- How do you avoid damaging the workpiece?

- How can you prevent heat discolouration?

- What can you do against corrosion?