Grinding and polishing stones

UNIVERSAL, CARBIDE

Grinding and polishing stones are versatile tools for finish machining on moulds in tool and mould-making. They are used for step-by-step fine grinding after machining or after electrical discharge machining (EDM) to grind in a brushed finish/polish in the demoulding direction or to prepare for high-gloss polishing with diamond pastes.

Advantages

- Long tool life.

- High dimensional stability.

- High abrasive performance.

- Even stock removal.

- Fine grinding pattern.

Applications

- Surface work

- Polishing

- Rounding

- Finishing

- Step-by-step fine grinding

PFERD TOOLS offers two different versions of grinding and polishing stones for different materials and applications.

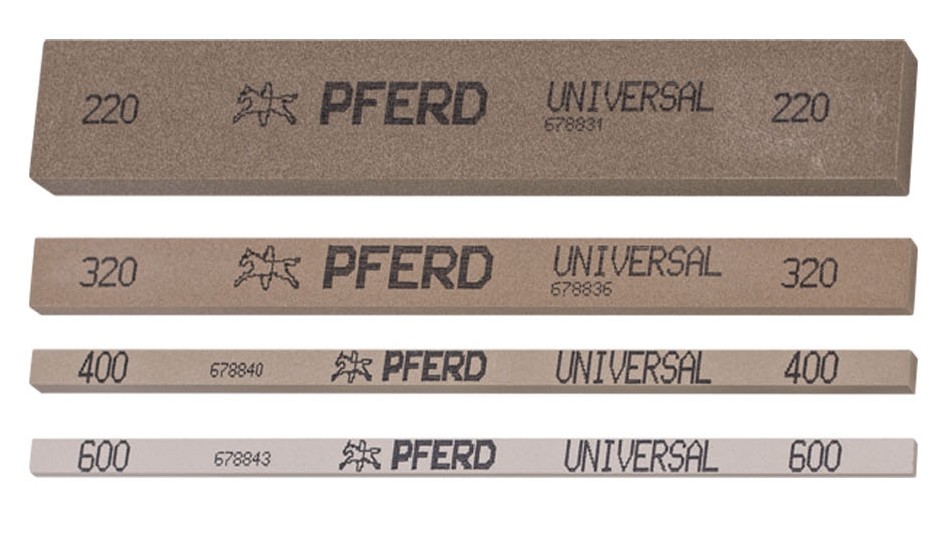

UNIVERSAL grinding and polishing stones

The UNIVERSAL grinding and polishing stones are all-rounders for step-by-step fine grinding. They are suitable for steels up to 1,200 N/mm2, stainless steel and non-ferrous metals, including soft and hard non-ferrous metals.

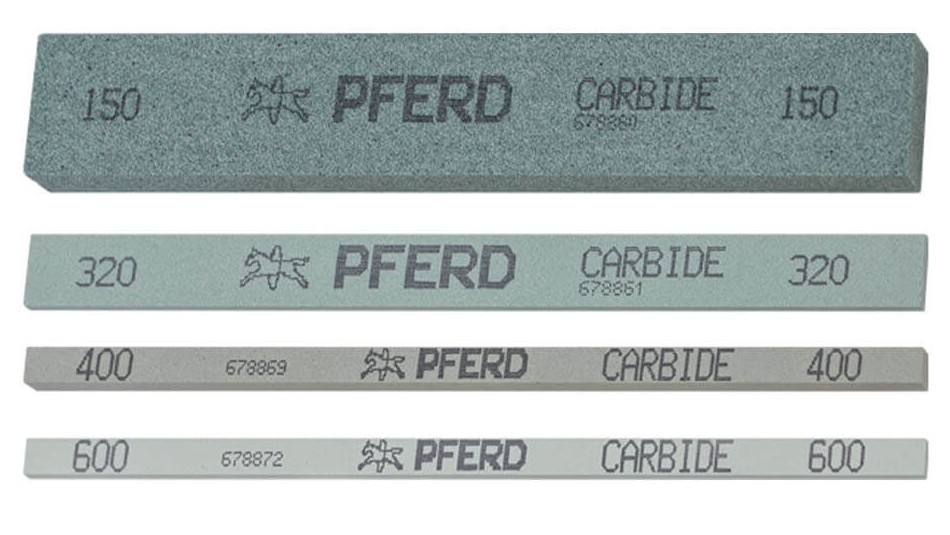

CARBIDE grinding and polishing stones

The CARBIDE soft grinding and polishing stones enable high removal rates without clogging on hard materials in tool and mould-making. They are ideal for hardened steels over 1,200 N/mm2 and tungsten carbide.

Application tips

- A quick-mounting handle is recommended in manual applications to make work more ergonomic.

- Grinding oil should be used to achieve a better surface finish.

- Polishing stones should be sorted by type to avoid grain being carried over.

- Grinding and polishing stones can be used with the PFGA 07/220 pneumatic filing machine.