Burrs for robot applications

PFERD TOOLS' impressive milling tools for robot applications meet the highest quality standards during production and offer high performance and wear resistance,

leading to significantly lower process costs and optimized process chains.

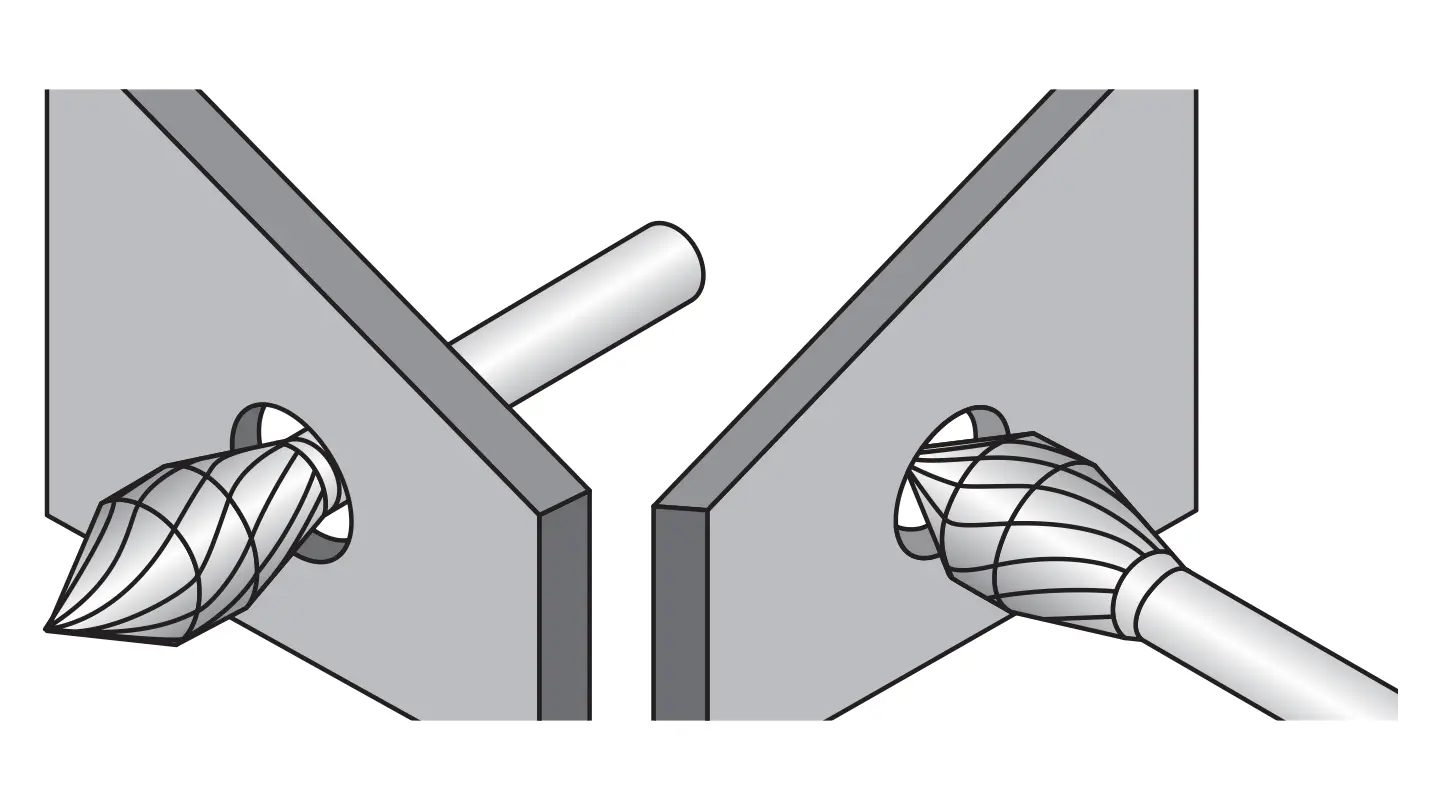

Special shape KZW

PFERD TOOLS has developed tungsten carbide burrs with the special shape KZW specifically for use in robot applications.

The special shape KZW combines three different burr shapes. This special geometry enables optimum chamfering and deburring in just one work step.

Benefit from reduced tool change times whilst also reducing the amount of programming work required.

All the benefits to you at a glance:

- Less programming needed due to fewer tool changes.

- High-quality HICOAT coating for a much longer tool life.

Our range includes the following versions:

PFERD TOOLS offers tungsten carbide burrs in the special shape KZW with the universal cut 3 and with the high-performance cut MICRO.

KZW cut 3 RS

with HICOAT coating HC-FEP

The tungsten carbide burrs KZW with cut 3 RS HC-FEP provide high stock removal on steel, cast iron, stainless steel (INOX), nickel-based alloys and titanium alloys and produce good surfaces.

KZW MICRO RS

with HICOAT coating HC-FEP

The tungsten carbide burrs KZW with cut MICRO RS HC-FEP enable users to work on almost all materials up to 68 HRC and produce a high surface quality.

Bespoke solutions

We are also happy to develop custom products for your robot applications. PFERD TOOLS has a long tradition of developing tools for robot applications. Our in-house research and development, along with our experienced application engineers, have successfully optimized numerous robotics applications around the world.