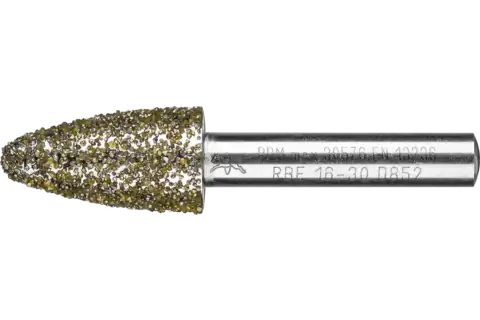

Diamond grinding points for foundries tree shape with radius end

Diamond grinding point tree shape with radius end dia. 16.0 mm shank dia. 8 mm D852 (very coarse) for grinding

DRBF-N 16-30/8 D 852

Technical information

Diamond grinding point tree shape with radius end dia. 16.0 mm shank dia. 8 mm D852 (very coarse) for grinding

- Dia. external

- 16 mm

- Dia. shank

- 8 mm

- Grit size

- D 852

- Length, shank

- 40

- Width

- 30 mm

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE